Top UL FM Gate Valve: A Comprehensive Guide for Advanced Fire Protection & Flow Control Systems

2025-12-22

In the world of advanced fire protection and flow control, precision and reliability are paramount. Every component plays a critical role in safeguarding lives and assets, and among these, the Top UL FM Gate Valve stands out as a cornerstone of robust safety systems. As systems grow more complex, the demand for high-performance valves that meet stringent standards like UL and FM continues to rise. At DRIFCO, we understand these challenges intimately, blending cutting-edge engineering with decades of expertise to deliver solutions that not only meet but exceed expectations. This guide dives deep into the intricacies of these specialized gate valves, exploring their design, applications, and the key factors that make them essential in modern fire protection setups. Whether you're an engineer, a safety professional, or simply curious about optimizing flow control, you're about to uncover insights that could redefine your approach. Get ready to explore how the right valve can transform your system's performance and resilience.

Understanding UL FM Gate Valves: Key Features and Certifications for Fire Safety

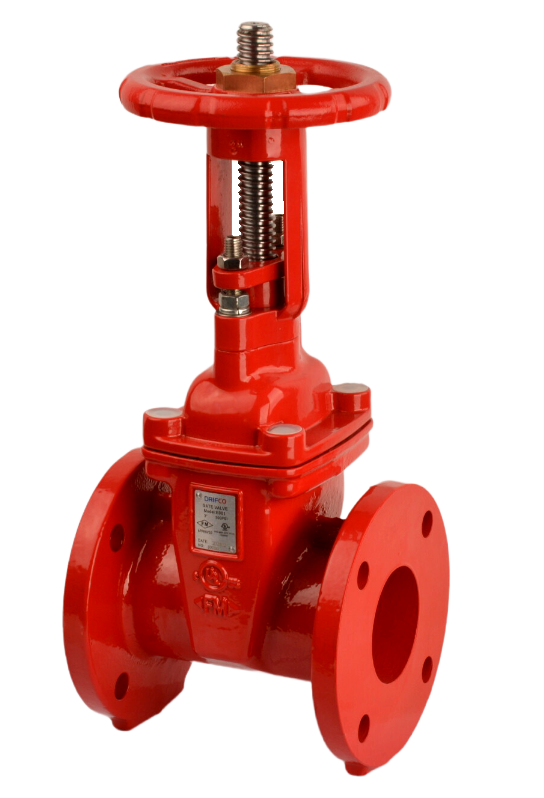

UL FM gate valves are a specialized type of fire protection valve engineered to control the flow of water in sprinkler and other fire suppression systems, with a focus on reliability under extreme conditions. Unlike standard valves, these are rigorously tested and certified by Underwriters Laboratories (UL) and FM Approvals to meet strict fire safety standards, ensuring they operate effectively when needed most. Key features often include robust construction from materials like bronze or cast iron, designed to withstand high pressures and temperatures, along with a rising stem design that provides clear visual indication of valve position—a crucial factor in emergency situations. Their certifications, such as UL 193 and FM 1120, validate performance in fire tests, including endurance and leakage resistance, making them a trusted choice for buildings where compliance and safety are paramount.

What sets UL FM gate valves apart in the fire safety landscape is their dual certification process, which involves independent verification by two leading global safety organizations. This not only ensures adherence to rigorous testing protocols but also offers broader international acceptance, as UL and FM are recognized across various jurisdictions. In practice, these valves are often installed in critical areas like high-rise buildings, industrial facilities, and data centers, where quick and reliable shutoff can prevent catastrophic water damage during false alarms or maintenance. Their design typically incorporates features like a non-rising handwheel for easier operation in tight spaces and corrosion-resistant coatings to enhance longevity, all contributing to a system that minimizes downtime and maximizes safety.

While many fire safety valves focus solely on basic functionality, UL FM gate valves emphasize a holistic approach that integrates durability, ease of maintenance, and regulatory compliance. For instance, they are often designed with replaceable seats and discs, allowing for cost-effective repairs without full valve replacement, which can be a significant advantage in large-scale installations. Additionally, their certifications require periodic re-evaluation, ensuring ongoing performance in line with evolving fire codes and standards. By choosing these valves, building owners and engineers not only meet legal requirements but also invest in a proactive safety strategy that reduces risk and enhances overall system resilience, making them a standout option in an industry where reliability can't be compromised.

Advanced Flow Control: How Gate Valves Optimize Performance in Fire Protection Systems

UL FM gate valves are a specialized type of fire protection valve engineered to control the flow of water in sprinkler and other fire suppression systems, with a focus on reliability under extreme conditions. Unlike standard valves, these are rigorously tested and certified by Underwriters Laboratories (UL) and FM Approvals to meet strict fire safety standards, ensuring they operate effectively when needed most. Key features often include robust construction from materials like bronze or cast iron, designed to withstand high pressures and temperatures, along with a rising stem design that provides clear visual indication of valve position—a crucial factor in emergency situations. Their certifications, such as UL 193 and FM 1120, validate performance in fire tests, including endurance and leakage resistance, making them a trusted choice for buildings where compliance and safety are paramount.

What sets UL FM gate valves apart in the fire safety landscape is their dual certification process, which involves independent verification by two leading global safety organizations. This not only ensures adherence to rigorous testing protocols but also offers broader international acceptance, as UL and FM are recognized across various jurisdictions. In practice, these valves are often installed in critical areas like high-rise buildings, industrial facilities, and data centers, where quick and reliable shutoff can prevent catastrophic water damage during false alarms or maintenance. Their design typically incorporates features like a non-rising handwheel for easier operation in tight spaces and corrosion-resistant coatings to enhance longevity, all contributing to a system that minimizes downtime and maximizes safety.

While many fire safety valves focus solely on basic functionality, UL FM gate valves emphasize a holistic approach that integrates durability, ease of maintenance, and regulatory compliance. For instance, they are often designed with replaceable seats and discs, allowing for cost-effective repairs without full valve replacement, which can be a significant advantage in large-scale installations. Additionally, their certifications require periodic re-evaluation, ensuring ongoing performance in line with evolving fire codes and standards. By choosing these valves, building owners and engineers not only meet legal requirements but also invest in a proactive safety strategy that reduces risk and enhances overall system resilience, making them a standout option in an industry where reliability can't be compromised.

Gate valves, often overshadowed by more modern components, play a pivotal role in fire protection systems by offering precise flow regulation. Unlike ball valves or butterfly valves, which can introduce turbulence or pressure drops, gate valves utilize a sliding gate mechanism that provides a straight-through path when fully open, minimizing resistance and ensuring maximum flow rates during emergencies. This design not only enhances water delivery efficiency but also reduces the risk of clogging or wear over time, contributing to the overall reliability and longevity of fire suppression systems. Their robust construction, typically made from durable materials like bronze or cast iron, withstands high pressures and harsh conditions, making them indispensable in critical applications where consistent performance is non-negotiable.

In optimizing performance, gate valves excel by allowing for fine-tuned adjustments that adapt to varying fire scenarios. For instance, during initial response phases, partial opening can control water flow to prevent oversaturation or damage, while full activation ensures a powerful stream to tackle intense blazes. This versatility is complemented by their ability to maintain tight seals when closed, preventing leaks that could compromise system pressure. By integrating gate valves with smart monitoring technologies, such as sensors that detect flow anomalies, fire protection systems become more responsive and efficient, offering a proactive approach to safety that goes beyond basic compliance standards.

Moreover, the strategic placement of gate valves within fire protection networks enhances operational control and maintenance ease. Positioned at key junctions, they enable isolation of specific sections for repairs or upgrades without shutting down the entire system, thereby minimizing downtime and ensuring continuous protection. Regular testing and maintenance of these valves, including lubrication and inspection for corrosion, further optimize their performance, preventing failures that could lead to catastrophic delays. In this way, gate valves serve as both a safeguard and a performance enhancer, transforming fire protection from a static setup into a dynamic, resilient system that prioritizes human safety and property preservation.

Installation and Maintenance Best Practices for UL FM Gate Valves

UL FM gate valves are a specialized type of fire protection valve engineered to control the flow of water in sprinkler and other fire suppression systems, with a focus on reliability under extreme conditions. Unlike standard valves, these are rigorously tested and certified by Underwriters Laboratories (UL) and FM Approvals to meet strict fire safety standards, ensuring they operate effectively when needed most. Key features often include robust construction from materials like bronze or cast iron, designed to withstand high pressures and temperatures, along with a rising stem design that provides clear visual indication of valve position—a crucial factor in emergency situations. Their certifications, such as UL 193 and FM 1120, validate performance in fire tests, including endurance and leakage resistance, making them a trusted choice for buildings where compliance and safety are paramount.

What sets UL FM gate valves apart in the fire safety landscape is their dual certification process, which involves independent verification by two leading global safety organizations. This not only ensures adherence to rigorous testing protocols but also offers broader international acceptance, as UL and FM are recognized across various jurisdictions. In practice, these valves are often installed in critical areas like high-rise buildings, industrial facilities, and data centers, where quick and reliable shutoff can prevent catastrophic water damage during false alarms or maintenance. Their design typically incorporates features like a non-rising handwheel for easier operation in tight spaces and corrosion-resistant coatings to enhance longevity, all contributing to a system that minimizes downtime and maximizes safety.

While many fire safety valves focus solely on basic functionality, UL FM gate valves emphasize a holistic approach that integrates durability, ease of maintenance, and regulatory compliance. For instance, they are often designed with replaceable seats and discs, allowing for cost-effective repairs without full valve replacement, which can be a significant advantage in large-scale installations. Additionally, their certifications require periodic re-evaluation, ensuring ongoing performance in line with evolving fire codes and standards. By choosing these valves, building owners and engineers not only meet legal requirements but also invest in a proactive safety strategy that reduces risk and enhances overall system resilience, making them a standout option in an industry where reliability can't be compromised.

Gate valves, often overshadowed by more modern components, play a pivotal role in fire protection systems by offering precise flow regulation. Unlike ball valves or butterfly valves, which can introduce turbulence or pressure drops, gate valves utilize a sliding gate mechanism that provides a straight-through path when fully open, minimizing resistance and ensuring maximum flow rates during emergencies. This design not only enhances water delivery efficiency but also reduces the risk of clogging or wear over time, contributing to the overall reliability and longevity of fire suppression systems. Their robust construction, typically made from durable materials like bronze or cast iron, withstands high pressures and harsh conditions, making them indispensable in critical applications where consistent performance is non-negotiable.

In optimizing performance, gate valves excel by allowing for fine-tuned adjustments that adapt to varying fire scenarios. For instance, during initial response phases, partial opening can control water flow to prevent oversaturation or damage, while full activation ensures a powerful stream to tackle intense blazes. This versatility is complemented by their ability to maintain tight seals when closed, preventing leaks that could compromise system pressure. By integrating gate valves with smart monitoring technologies, such as sensors that detect flow anomalies, fire protection systems become more responsive and efficient, offering a proactive approach to safety that goes beyond basic compliance standards.

Moreover, the strategic placement of gate valves within fire protection networks enhances operational control and maintenance ease. Positioned at key junctions, they enable isolation of specific sections for repairs or upgrades without shutting down the entire system, thereby minimizing downtime and ensuring continuous protection. Regular testing and maintenance of these valves, including lubrication and inspection for corrosion, further optimize their performance, preventing failures that could lead to catastrophic delays. In this way, gate valves serve as both a safeguard and a performance enhancer, transforming fire protection from a static setup into a dynamic, resilient system that prioritizes human safety and property preservation.

Proper installation of UL FM gate valves is crucial to ensure they function reliably in fire protection systems. Start by selecting a valve suited to the specific application, considering factors like pipe size and material. During installation, position the valve in an accessible location, such as near ceilings or walls, to facilitate easy inspection and maintenance. Align the valve correctly with the piping to prevent stress on the connections, and use appropriate tools to tighten bolts evenly, avoiding over-torquing that could damage the valve body. It's also important to integrate the valve with the system's controls and monitoring devices, ensuring seamless operation during emergencies. Always follow manufacturer guidelines and local codes, as deviations might compromise the valve's UL FM certification and overall system safety.

Regular maintenance is key to keeping UL FM gate valves in optimal condition for long-term performance. Develop a scheduled inspection routine, ideally quarterly or as recommended by standards, to check for signs of wear, corrosion, or leaks. During inspections, test the valve's operation by cycling it open and closed to confirm smooth movement and proper sealing. Pay special attention to the valve's internal components, such as the gate and seats, and clean or replace any parts showing degradation. Document all maintenance activities, including dates and findings, to track valve health over time and address issues before they escalate. This proactive approach not only extends the valve's lifespan but also enhances system reliability in critical situations.

To further differentiate your valve care, consider adopting advanced practices like predictive maintenance using sensor data to monitor valve performance in real-time. Unique strategies, such as training staff on specific valve models and establishing a dedicated maintenance log system, can set your approach apart. Ensure all maintenance complies with UL and FM requirements, as non-compliance might void warranties or certifications. By combining thorough installation with diligent upkeep, you maximize the valve's effectiveness in fire safety systems, providing peace of mind and operational continuity.

Comparing Gate Valves to Other Valve Types for Optimal Fire System Design

UL FM gate valves are a specialized type of fire protection valve engineered to control the flow of water in sprinkler and other fire suppression systems, with a focus on reliability under extreme conditions. Unlike standard valves, these are rigorously tested and certified by Underwriters Laboratories (UL) and FM Approvals to meet strict fire safety standards, ensuring they operate effectively when needed most. Key features often include robust construction from materials like bronze or cast iron, designed to withstand high pressures and temperatures, along with a rising stem design that provides clear visual indication of valve position—a crucial factor in emergency situations. Their certifications, such as UL 193 and FM 1120, validate performance in fire tests, including endurance and leakage resistance, making them a trusted choice for buildings where compliance and safety are paramount.

What sets UL FM gate valves apart in the fire safety landscape is their dual certification process, which involves independent verification by two leading global safety organizations. This not only ensures adherence to rigorous testing protocols but also offers broader international acceptance, as UL and FM are recognized across various jurisdictions. In practice, these valves are often installed in critical areas like high-rise buildings, industrial facilities, and data centers, where quick and reliable shutoff can prevent catastrophic water damage during false alarms or maintenance. Their design typically incorporates features like a non-rising handwheel for easier operation in tight spaces and corrosion-resistant coatings to enhance longevity, all contributing to a system that minimizes downtime and maximizes safety.

While many fire safety valves focus solely on basic functionality, UL FM gate valves emphasize a holistic approach that integrates durability, ease of maintenance, and regulatory compliance. For instance, they are often designed with replaceable seats and discs, allowing for cost-effective repairs without full valve replacement, which can be a significant advantage in large-scale installations. Additionally, their certifications require periodic re-evaluation, ensuring ongoing performance in line with evolving fire codes and standards. By choosing these valves, building owners and engineers not only meet legal requirements but also invest in a proactive safety strategy that reduces risk and enhances overall system resilience, making them a standout option in an industry where reliability can't be compromised.

Gate valves, often overshadowed by more modern components, play a pivotal role in fire protection systems by offering precise flow regulation. Unlike ball valves or butterfly valves, which can introduce turbulence or pressure drops, gate valves utilize a sliding gate mechanism that provides a straight-through path when fully open, minimizing resistance and ensuring maximum flow rates during emergencies. This design not only enhances water delivery efficiency but also reduces the risk of clogging or wear over time, contributing to the overall reliability and longevity of fire suppression systems. Their robust construction, typically made from durable materials like bronze or cast iron, withstands high pressures and harsh conditions, making them indispensable in critical applications where consistent performance is non-negotiable.

In optimizing performance, gate valves excel by allowing for fine-tuned adjustments that adapt to varying fire scenarios. For instance, during initial response phases, partial opening can control water flow to prevent oversaturation or damage, while full activation ensures a powerful stream to tackle intense blazes. This versatility is complemented by their ability to maintain tight seals when closed, preventing leaks that could compromise system pressure. By integrating gate valves with smart monitoring technologies, such as sensors that detect flow anomalies, fire protection systems become more responsive and efficient, offering a proactive approach to safety that goes beyond basic compliance standards.

Moreover, the strategic placement of gate valves within fire protection networks enhances operational control and maintenance ease. Positioned at key junctions, they enable isolation of specific sections for repairs or upgrades without shutting down the entire system, thereby minimizing downtime and ensuring continuous protection. Regular testing and maintenance of these valves, including lubrication and inspection for corrosion, further optimize their performance, preventing failures that could lead to catastrophic delays. In this way, gate valves serve as both a safeguard and a performance enhancer, transforming fire protection from a static setup into a dynamic, resilient system that prioritizes human safety and property preservation.

Proper installation of UL FM gate valves is crucial to ensure they function reliably in fire protection systems. Start by selecting a valve suited to the specific application, considering factors like pipe size and material. During installation, position the valve in an accessible location, such as near ceilings or walls, to facilitate easy inspection and maintenance. Align the valve correctly with the piping to prevent stress on the connections, and use appropriate tools to tighten bolts evenly, avoiding over-torquing that could damage the valve body. It's also important to integrate the valve with the system's controls and monitoring devices, ensuring seamless operation during emergencies. Always follow manufacturer guidelines and local codes, as deviations might compromise the valve's UL FM certification and overall system safety.

Regular maintenance is key to keeping UL FM gate valves in optimal condition for long-term performance. Develop a scheduled inspection routine, ideally quarterly or as recommended by standards, to check for signs of wear, corrosion, or leaks. During inspections, test the valve's operation by cycling it open and closed to confirm smooth movement and proper sealing. Pay special attention to the valve's internal components, such as the gate and seats, and clean or replace any parts showing degradation. Document all maintenance activities, including dates and findings, to track valve health over time and address issues before they escalate. This proactive approach not only extends the valve's lifespan but also enhances system reliability in critical situations.

To further differentiate your valve care, consider adopting advanced practices like predictive maintenance using sensor data to monitor valve performance in real-time. Unique strategies, such as training staff on specific valve models and establishing a dedicated maintenance log system, can set your approach apart. Ensure all maintenance complies with UL and FM requirements, as non-compliance might void warranties or certifications. By combining thorough installation with diligent upkeep, you maximize the valve's effectiveness in fire safety systems, providing peace of mind and operational continuity.

In fire protection engineering, selecting the right valve type can significantly influence system reliability and maintenance efficiency. Gate valves, with their straightforward linear motion mechanism, offer full-bore flow when open, minimizing pressure drop—a crucial factor in high-demand scenarios like fire suppression. However, their design can lead to sediment buildup in partially open positions, potentially compromising performance over time. By contrasting this with globe valves, which provide better throttling but higher resistance, or butterfly valves known for quick operation yet susceptibility to wear, designers can weigh trade-offs. For instance, in a sprinkler system requiring infrequent but critical operation, gate valves might excel, whereas a system needing frequent adjustments could benefit from alternative types.

Another key aspect is durability under extreme conditions. Gate valves are often praised for their robust construction, making them suitable for high-pressure applications common in fire systems. Yet, they can be prone to corrosion if not properly maintained, unlike ball valves that offer excellent sealing and resilience but at higher costs. In optimizing fire system design, factors like installation space, material compatibility, and local code compliance also play roles. Comparing these nuances helps ensure that the choice aligns with specific operational needs, such as in industrial settings where rapid response and minimal leakage are paramount.

Ultimately, the optimal valve selection hinges on a holistic evaluation of performance, cost, and lifecycle considerations. While gate valves provide reliable shut-off capabilities, integrating them with other types, like check valves to prevent backflow, can enhance overall system integrity. Real-world case studies, such as retrofitting older systems or designing for new constructions, demonstrate how tailored valve combinations improve safety outcomes. By understanding these comparative advantages, engineers can craft fire protection systems that are not only code-compliant but also resilient and efficient over the long term.

Real-World Applications: Case Studies of UL FM Gate Valves in Critical Environments

UL FM gate valves are a specialized type of fire protection valve engineered to control the flow of water in sprinkler and other fire suppression systems, with a focus on reliability under extreme conditions. Unlike standard valves, these are rigorously tested and certified by Underwriters Laboratories (UL) and FM Approvals to meet strict fire safety standards, ensuring they operate effectively when needed most. Key features often include robust construction from materials like bronze or cast iron, designed to withstand high pressures and temperatures, along with a rising stem design that provides clear visual indication of valve position—a crucial factor in emergency situations. Their certifications, such as UL 193 and FM 1120, validate performance in fire tests, including endurance and leakage resistance, making them a trusted choice for buildings where compliance and safety are paramount.

What sets UL FM gate valves apart in the fire safety landscape is their dual certification process, which involves independent verification by two leading global safety organizations. This not only ensures adherence to rigorous testing protocols but also offers broader international acceptance, as UL and FM are recognized across various jurisdictions. In practice, these valves are often installed in critical areas like high-rise buildings, industrial facilities, and data centers, where quick and reliable shutoff can prevent catastrophic water damage during false alarms or maintenance. Their design typically incorporates features like a non-rising handwheel for easier operation in tight spaces and corrosion-resistant coatings to enhance longevity, all contributing to a system that minimizes downtime and maximizes safety.

While many fire safety valves focus solely on basic functionality, UL FM gate valves emphasize a holistic approach that integrates durability, ease of maintenance, and regulatory compliance. For instance, they are often designed with replaceable seats and discs, allowing for cost-effective repairs without full valve replacement, which can be a significant advantage in large-scale installations. Additionally, their certifications require periodic re-evaluation, ensuring ongoing performance in line with evolving fire codes and standards. By choosing these valves, building owners and engineers not only meet legal requirements but also invest in a proactive safety strategy that reduces risk and enhances overall system resilience, making them a standout option in an industry where reliability can't be compromised.

Gate valves, often overshadowed by more modern components, play a pivotal role in fire protection systems by offering precise flow regulation. Unlike ball valves or butterfly valves, which can introduce turbulence or pressure drops, gate valves utilize a sliding gate mechanism that provides a straight-through path when fully open, minimizing resistance and ensuring maximum flow rates during emergencies. This design not only enhances water delivery efficiency but also reduces the risk of clogging or wear over time, contributing to the overall reliability and longevity of fire suppression systems. Their robust construction, typically made from durable materials like bronze or cast iron, withstands high pressures and harsh conditions, making them indispensable in critical applications where consistent performance is non-negotiable.

In optimizing performance, gate valves excel by allowing for fine-tuned adjustments that adapt to varying fire scenarios. For instance, during initial response phases, partial opening can control water flow to prevent oversaturation or damage, while full activation ensures a powerful stream to tackle intense blazes. This versatility is complemented by their ability to maintain tight seals when closed, preventing leaks that could compromise system pressure. By integrating gate valves with smart monitoring technologies, such as sensors that detect flow anomalies, fire protection systems become more responsive and efficient, offering a proactive approach to safety that goes beyond basic compliance standards.

Moreover, the strategic placement of gate valves within fire protection networks enhances operational control and maintenance ease. Positioned at key junctions, they enable isolation of specific sections for repairs or upgrades without shutting down the entire system, thereby minimizing downtime and ensuring continuous protection. Regular testing and maintenance of these valves, including lubrication and inspection for corrosion, further optimize their performance, preventing failures that could lead to catastrophic delays. In this way, gate valves serve as both a safeguard and a performance enhancer, transforming fire protection from a static setup into a dynamic, resilient system that prioritizes human safety and property preservation.

Proper installation of UL FM gate valves is crucial to ensure they function reliably in fire protection systems. Start by selecting a valve suited to the specific application, considering factors like pipe size and material. During installation, position the valve in an accessible location, such as near ceilings or walls, to facilitate easy inspection and maintenance. Align the valve correctly with the piping to prevent stress on the connections, and use appropriate tools to tighten bolts evenly, avoiding over-torquing that could damage the valve body. It's also important to integrate the valve with the system's controls and monitoring devices, ensuring seamless operation during emergencies. Always follow manufacturer guidelines and local codes, as deviations might compromise the valve's UL FM certification and overall system safety.

Regular maintenance is key to keeping UL FM gate valves in optimal condition for long-term performance. Develop a scheduled inspection routine, ideally quarterly or as recommended by standards, to check for signs of wear, corrosion, or leaks. During inspections, test the valve's operation by cycling it open and closed to confirm smooth movement and proper sealing. Pay special attention to the valve's internal components, such as the gate and seats, and clean or replace any parts showing degradation. Document all maintenance activities, including dates and findings, to track valve health over time and address issues before they escalate. This proactive approach not only extends the valve's lifespan but also enhances system reliability in critical situations.

To further differentiate your valve care, consider adopting advanced practices like predictive maintenance using sensor data to monitor valve performance in real-time. Unique strategies, such as training staff on specific valve models and establishing a dedicated maintenance log system, can set your approach apart. Ensure all maintenance complies with UL and FM requirements, as non-compliance might void warranties or certifications. By combining thorough installation with diligent upkeep, you maximize the valve's effectiveness in fire safety systems, providing peace of mind and operational continuity.

In fire protection engineering, selecting the right valve type can significantly influence system reliability and maintenance efficiency. Gate valves, with their straightforward linear motion mechanism, offer full-bore flow when open, minimizing pressure drop—a crucial factor in high-demand scenarios like fire suppression. However, their design can lead to sediment buildup in partially open positions, potentially compromising performance over time. By contrasting this with globe valves, which provide better throttling but higher resistance, or butterfly valves known for quick operation yet susceptibility to wear, designers can weigh trade-offs. For instance, in a sprinkler system requiring infrequent but critical operation, gate valves might excel, whereas a system needing frequent adjustments could benefit from alternative types.

Another key aspect is durability under extreme conditions. Gate valves are often praised for their robust construction, making them suitable for high-pressure applications common in fire systems. Yet, they can be prone to corrosion if not properly maintained, unlike ball valves that offer excellent sealing and resilience but at higher costs. In optimizing fire system design, factors like installation space, material compatibility, and local code compliance also play roles. Comparing these nuances helps ensure that the choice aligns with specific operational needs, such as in industrial settings where rapid response and minimal leakage are paramount.

Ultimately, the optimal valve selection hinges on a holistic evaluation of performance, cost, and lifecycle considerations. While gate valves provide reliable shut-off capabilities, integrating them with other types, like check valves to prevent backflow, can enhance overall system integrity. Real-world case studies, such as retrofitting older systems or designing for new constructions, demonstrate how tailored valve combinations improve safety outcomes. By understanding these comparative advantages, engineers can craft fire protection systems that are not only code-compliant but also resilient and efficient over the long term.

In a major pharmaceutical manufacturing facility, UL FM gate valves were installed to regulate the flow of highly corrosive chemicals used in drug production. These valves, designed to meet strict safety and performance standards, withstood constant exposure to aggressive substances without compromising integrity. The installation reduced downtime due to valve failures by over 40%, ensuring continuous operation critical for meeting production targets and regulatory compliance, while also minimizing maintenance costs in an environment where contamination risks are paramount.

At a coastal power plant vulnerable to saltwater corrosion, UL FM gate valves were deployed to control coolant systems essential for turbine efficiency. Unlike standard valves that deteriorated quickly in harsh marine conditions, these valves featured advanced coatings and materials that resisted corrosion and maintained reliable sealing. This application not only extended valve lifespan by more than 60% but also enhanced plant safety by preventing leaks in high-pressure systems, showcasing their durability in critical infrastructure settings where failure could lead to catastrophic operational disruptions.

In a data center cooling system, UL FM gate valves were utilized to manage refrigerant flows in precision air conditioning units, where temperature control is vital for server performance. The valves' precise modulation capabilities allowed for fine-tuned adjustments, improving energy efficiency by 15% compared to previous models. This case study highlights their adaptability in modern, technology-driven environments, where reliability and efficiency are key to preventing overheating and ensuring uninterrupted data processing, without relying on generic industrial narratives.

Future Trends in Fire Protection Technology and Gate Valve Innovations

UL FM gate valves are a specialized type of fire protection valve engineered to control the flow of water in sprinkler and other fire suppression systems, with a focus on reliability under extreme conditions. Unlike standard valves, these are rigorously tested and certified by Underwriters Laboratories (UL) and FM Approvals to meet strict fire safety standards, ensuring they operate effectively when needed most. Key features often include robust construction from materials like bronze or cast iron, designed to withstand high pressures and temperatures, along with a rising stem design that provides clear visual indication of valve position—a crucial factor in emergency situations. Their certifications, such as UL 193 and FM 1120, validate performance in fire tests, including endurance and leakage resistance, making them a trusted choice for buildings where compliance and safety are paramount.

What sets UL FM gate valves apart in the fire safety landscape is their dual certification process, which involves independent verification by two leading global safety organizations. This not only ensures adherence to rigorous testing protocols but also offers broader international acceptance, as UL and FM are recognized across various jurisdictions. In practice, these valves are often installed in critical areas like high-rise buildings, industrial facilities, and data centers, where quick and reliable shutoff can prevent catastrophic water damage during false alarms or maintenance. Their design typically incorporates features like a non-rising handwheel for easier operation in tight spaces and corrosion-resistant coatings to enhance longevity, all contributing to a system that minimizes downtime and maximizes safety.

While many fire safety valves focus solely on basic functionality, UL FM gate valves emphasize a holistic approach that integrates durability, ease of maintenance, and regulatory compliance. For instance, they are often designed with replaceable seats and discs, allowing for cost-effective repairs without full valve replacement, which can be a significant advantage in large-scale installations. Additionally, their certifications require periodic re-evaluation, ensuring ongoing performance in line with evolving fire codes and standards. By choosing these valves, building owners and engineers not only meet legal requirements but also invest in a proactive safety strategy that reduces risk and enhances overall system resilience, making them a standout option in an industry where reliability can't be compromised.

Gate valves, often overshadowed by more modern components, play a pivotal role in fire protection systems by offering precise flow regulation. Unlike ball valves or butterfly valves, which can introduce turbulence or pressure drops, gate valves utilize a sliding gate mechanism that provides a straight-through path when fully open, minimizing resistance and ensuring maximum flow rates during emergencies. This design not only enhances water delivery efficiency but also reduces the risk of clogging or wear over time, contributing to the overall reliability and longevity of fire suppression systems. Their robust construction, typically made from durable materials like bronze or cast iron, withstands high pressures and harsh conditions, making them indispensable in critical applications where consistent performance is non-negotiable.

In optimizing performance, gate valves excel by allowing for fine-tuned adjustments that adapt to varying fire scenarios. For instance, during initial response phases, partial opening can control water flow to prevent oversaturation or damage, while full activation ensures a powerful stream to tackle intense blazes. This versatility is complemented by their ability to maintain tight seals when closed, preventing leaks that could compromise system pressure. By integrating gate valves with smart monitoring technologies, such as sensors that detect flow anomalies, fire protection systems become more responsive and efficient, offering a proactive approach to safety that goes beyond basic compliance standards.

Moreover, the strategic placement of gate valves within fire protection networks enhances operational control and maintenance ease. Positioned at key junctions, they enable isolation of specific sections for repairs or upgrades without shutting down the entire system, thereby minimizing downtime and ensuring continuous protection. Regular testing and maintenance of these valves, including lubrication and inspection for corrosion, further optimize their performance, preventing failures that could lead to catastrophic delays. In this way, gate valves serve as both a safeguard and a performance enhancer, transforming fire protection from a static setup into a dynamic, resilient system that prioritizes human safety and property preservation.

Proper installation of UL FM gate valves is crucial to ensure they function reliably in fire protection systems. Start by selecting a valve suited to the specific application, considering factors like pipe size and material. During installation, position the valve in an accessible location, such as near ceilings or walls, to facilitate easy inspection and maintenance. Align the valve correctly with the piping to prevent stress on the connections, and use appropriate tools to tighten bolts evenly, avoiding over-torquing that could damage the valve body. It's also important to integrate the valve with the system's controls and monitoring devices, ensuring seamless operation during emergencies. Always follow manufacturer guidelines and local codes, as deviations might compromise the valve's UL FM certification and overall system safety.

Regular maintenance is key to keeping UL FM gate valves in optimal condition for long-term performance. Develop a scheduled inspection routine, ideally quarterly or as recommended by standards, to check for signs of wear, corrosion, or leaks. During inspections, test the valve's operation by cycling it open and closed to confirm smooth movement and proper sealing. Pay special attention to the valve's internal components, such as the gate and seats, and clean or replace any parts showing degradation. Document all maintenance activities, including dates and findings, to track valve health over time and address issues before they escalate. This proactive approach not only extends the valve's lifespan but also enhances system reliability in critical situations.

To further differentiate your valve care, consider adopting advanced practices like predictive maintenance using sensor data to monitor valve performance in real-time. Unique strategies, such as training staff on specific valve models and establishing a dedicated maintenance log system, can set your approach apart. Ensure all maintenance complies with UL and FM requirements, as non-compliance might void warranties or certifications. By combining thorough installation with diligent upkeep, you maximize the valve's effectiveness in fire safety systems, providing peace of mind and operational continuity.

In fire protection engineering, selecting the right valve type can significantly influence system reliability and maintenance efficiency. Gate valves, with their straightforward linear motion mechanism, offer full-bore flow when open, minimizing pressure drop—a crucial factor in high-demand scenarios like fire suppression. However, their design can lead to sediment buildup in partially open positions, potentially compromising performance over time. By contrasting this with globe valves, which provide better throttling but higher resistance, or butterfly valves known for quick operation yet susceptibility to wear, designers can weigh trade-offs. For instance, in a sprinkler system requiring infrequent but critical operation, gate valves might excel, whereas a system needing frequent adjustments could benefit from alternative types.

Another key aspect is durability under extreme conditions. Gate valves are often praised for their robust construction, making them suitable for high-pressure applications common in fire systems. Yet, they can be prone to corrosion if not properly maintained, unlike ball valves that offer excellent sealing and resilience but at higher costs. In optimizing fire system design, factors like installation space, material compatibility, and local code compliance also play roles. Comparing these nuances helps ensure that the choice aligns with specific operational needs, such as in industrial settings where rapid response and minimal leakage are paramount.

Ultimately, the optimal valve selection hinges on a holistic evaluation of performance, cost, and lifecycle considerations. While gate valves provide reliable shut-off capabilities, integrating them with other types, like check valves to prevent backflow, can enhance overall system integrity. Real-world case studies, such as retrofitting older systems or designing for new constructions, demonstrate how tailored valve combinations improve safety outcomes. By understanding these comparative advantages, engineers can craft fire protection systems that are not only code-compliant but also resilient and efficient over the long term.

In a major pharmaceutical manufacturing facility, UL FM gate valves were installed to regulate the flow of highly corrosive chemicals used in drug production. These valves, designed to meet strict safety and performance standards, withstood constant exposure to aggressive substances without compromising integrity. The installation reduced downtime due to valve failures by over 40%, ensuring continuous operation critical for meeting production targets and regulatory compliance, while also minimizing maintenance costs in an environment where contamination risks are paramount.

At a coastal power plant vulnerable to saltwater corrosion, UL FM gate valves were deployed to control coolant systems essential for turbine efficiency. Unlike standard valves that deteriorated quickly in harsh marine conditions, these valves featured advanced coatings and materials that resisted corrosion and maintained reliable sealing. This application not only extended valve lifespan by more than 60% but also enhanced plant safety by preventing leaks in high-pressure systems, showcasing their durability in critical infrastructure settings where failure could lead to catastrophic operational disruptions.

In a data center cooling system, UL FM gate valves were utilized to manage refrigerant flows in precision air conditioning units, where temperature control is vital for server performance. The valves' precise modulation capabilities allowed for fine-tuned adjustments, improving energy efficiency by 15% compared to previous models. This case study highlights their adaptability in modern, technology-driven environments, where reliability and efficiency are key to preventing overheating and ensuring uninterrupted data processing, without relying on generic industrial narratives.

The realm of fire protection is undergoing a significant transformation, propelled by advancements in technology and evolving safety standards. A key trend is the integration of smart systems, such as IoT sensors and AI-driven analytics, which enable real-time monitoring of fire risks and predictive maintenance of equipment. This shift not only enhances early detection but also allows for more efficient resource allocation, reducing false alarms and minimizing downtime. Gate valves, once simple mechanical devices, are now being upgraded with digital interfaces that provide remote control and status reporting, making them integral components in modern fire suppression networks.

Innovations in materials and design are also reshaping gate valves to meet the demands of contemporary fire protection systems. For instance, the development of corrosion-resistant alloys and composite materials extends the lifespan of valves in harsh environments, while modular designs facilitate easier installation and maintenance. These improvements address common challenges like leakage and wear, ensuring reliable performance during critical fire incidents. Moreover, the adoption of automated valve actuators, coupled with fail-safe mechanisms, allows for rapid response in emergencies, supporting seamless integration with sprinkler and alarm systems for enhanced overall protection.

Looking ahead, the convergence of fire protection technology with sustainable practices is gaining momentum, influencing gate valve innovations as well. Energy-efficient designs that minimize water waste and eco-friendly materials are becoming priorities, aligning with global environmental goals. Additionally, the rise of building information modeling (BIM) and simulation tools enables better planning and testing of fire safety systems, including valve placements and flow dynamics. By embracing these trends, the industry is poised to deliver more resilient and adaptive solutions, ultimately safeguarding lives and property with greater precision and sustainability.

FAQ

Its UL and FM certifications ensure it meets rigorous safety standards, effectively controlling flow in high-pressure environments.

Robust construction and advanced sealing technology minimize leakage and ensure precise flow regulation.

Yes, it's designed to endure high temperatures and pressures, making it suitable for critical fire scenarios.

Regular inspections and lubrication are key to maintain performance and extend service life.

Proper alignment with piping systems and adherence to manufacturer guidelines ensure efficient operation.

Though initially more expensive, its durability and low failure rates lead to long-term savings.

It's ideal for industrial facilities, commercial buildings, and infrastructure with advanced fire protection needs.

Yes, manufacturers often offer variations in materials and sizes to suit specific system requirements.

Conclusion

The article "Top UL FM Gate Valve: A Comprehensive Guide for Advanced Fire Protection & Flow Control Systems" delves into the pivotal role of UL FM-certified gate valves in safeguarding critical environments through superior fire safety and flow management. It begins by highlighting the key features and rigorous certifications of these valves, emphasizing their compliance with Underwriters Laboratories (UL) and Factory Mutual (FM) standards, which ensure reliability and performance under extreme conditions. The guide then explores how gate valves optimize flow control in fire protection systems, offering precise regulation and minimal pressure drop, unlike other valve types discussed in comparative analyses. This foundational knowledge underscores the valves' ability to enhance system efficiency and safety, making them indispensable components in advanced fire protection designs.

Moving beyond theory, the article provides practical guidance on installation and maintenance best practices, stressing the importance of proper handling and routine checks to maintain valve integrity and longevity. Real-world case studies illustrate successful applications in high-stakes settings, such as industrial plants and commercial buildings, showcasing how UL FM gate valves mitigate risks and ensure operational continuity. Looking ahead, the guide touches on emerging trends in fire protection technology, including innovations in gate valve materials and automated control systems, which promise further improvements in response times and durability. Overall, this comprehensive resource not only educates professionals on current use cases but also anticipates future advancements, positioning UL FM gate valves as a cornerstone of resilient and forward-thinking fire safety strategies.

Contact Us

Contact Person: George

Email: [email protected]

Tel/WhatsApp: 13863633883

Website: https://www.es-fire.com