Gate Valve Factory Insights: Leading UL FM Certified Manufacturing for Superior Fire Safety Solutions

2025-12-23

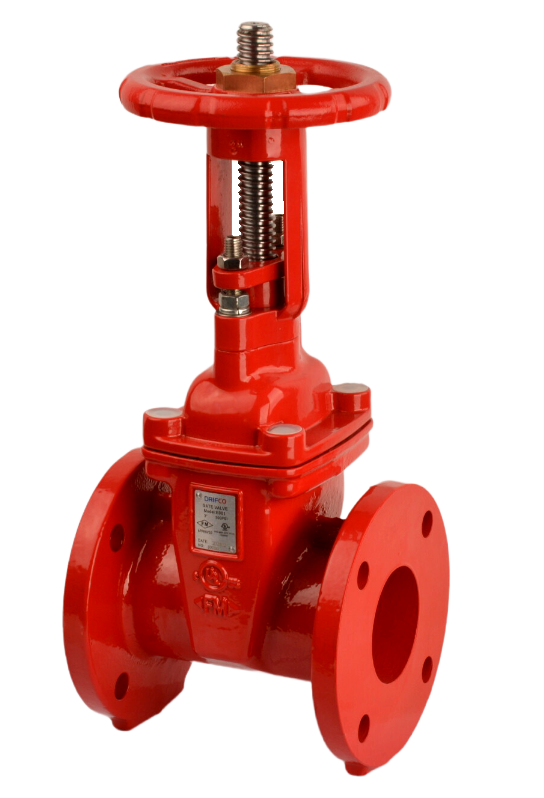

In the critical world of fire safety solutions, every component must perform flawlessly to protect lives and property. At the forefront of this industry, DRIFCO has established itself as a premier Gate Valve Factory, offering cutting-edge manufacturing with UL FM certification that sets new benchmarks for reliability and safety. Our dedication to superior engineering ensures that each valve not only meets but exceeds stringent standards, providing peace of mind in high-stakes environments. As you explore this blog, you'll uncover the insights and innovations that make DRIFCO a trusted name in fire protection. From advanced production techniques to rigorous quality controls, we invite you to delve into how our expertise translates into tangible safety benefits. Whether you're a professional in the field or simply passionate about safeguarding communities, this journey into our factory's core will illuminate why DRIFCO stands as a leader. Stay tuned to learn more about our commitment to excellence and how we're shaping the future of fire safety solutions, one valve at a time.

Exploring the Core Excellence of Gate Valve Production

Gate valve production isn't just about manufacturing components; it's a finely tuned craft that demands precision engineering and rigorous quality control. At its heart, excellence stems from the meticulous selection of materials—think high-grade stainless steel, brass, or alloys tailored for durability—ensuring each valve withstands harsh environments and volatile pressures. Skilled technicians employ advanced CNC machining and automated assembly to achieve tight tolerances, minimizing leaks and boosting longevity. This blend of artisanal expertise and cutting-edge technology results in valves that perform reliably, whether in industrial plants or municipal water systems.

Beyond technical prowess, core excellence in gate valve production hinges on innovative design and thorough testing. Manufacturers integrate features like wedge mechanisms for smoother operation or corrosion-resistant coatings to combat wear. Each unit undergoes stress tests, flow simulations, and cycle checks to confirm it meets stringent safety standards. This commitment to innovation not only enhances functionality but also reduces maintenance needs, making these valves a smart investment for critical applications. It's this forward-thinking approach that sets leading producers apart in a competitive market.

Ultimately, the excellence of gate valve production lies in its holistic approach—where sustainability and customer-centric solutions converge. Many top manufacturers now prioritize eco-friendly practices, such as using recycled materials or minimizing waste during fabrication. Coupled with custom engineering services, from valve sizing to after-sales support, this ensures clients get tailored products that fit their specific needs. By fostering continuous improvement and adapting to evolving industry demands, producers uphold a reputation for excellence that goes beyond mere craftsmanship, delivering value and reliability in every valve.

Why UL FM Certification Elevates Fire Safety Standards

When it comes to fire safety, not all certifications carry the same weight. UL listing is widely recognized, but FM approval—issued by FM Global, a major commercial property insurer—adds a rigorous layer of scrutiny that directly addresses real-world fire risks in industrial and commercial settings. Unlike basic standards that focus on component performance, FM certification involves holistic testing of entire systems under extreme conditions, simulating scenarios like prolonged exposure to heat or aggressive fire suppression agents. This ensures that products not only meet minimum requirements but are robust enough to withstand the unpredictable nature of actual fires, reducing the likelihood of failure when it matters most.

What sets UL FM certification apart is its insurer-driven approach, which ties directly to risk mitigation and loss prevention. FM Global’s research labs conduct extensive tests based on decades of claims data, targeting specific vulnerabilities that lead to costly fires. For example, they might evaluate how a fire alarm system performs in high-humidity environments or test sprinkler components for resistance to corrosion over time. This focus on durability and environmental factors means certified products are vetted for long-term reliability, not just initial compliance. For facility managers and insurers, this translates to lower risk profiles and potential reductions in premiums, making it a smart investment in both safety and economics.

In practice, opting for UL FM-certified equipment can transform safety protocols from a regulatory checkbox into a proactive defense strategy. These products often incorporate advanced materials or designs—such as heat-resistant coatings or redundant activation mechanisms—that go beyond standard codes. By choosing certified solutions, organizations signal a commitment to exceeding baseline expectations, fostering a culture of safety that prioritizes prevention over reaction. This not only enhances protection for assets and personnel but also builds trust with stakeholders, as the certification is globally acknowledged as a mark of excellence in fire safety innovation and resilience.

Innovative Manufacturing Techniques for Enhanced Durability

When it comes to boosting durability in modern products, innovative manufacturing techniques are game-changers, shifting away from traditional methods that often prioritize cost over longevity. For instance, additive manufacturing, commonly known as 3D printing, allows for the creation of complex geometries with reduced material waste and enhanced structural integrity. This isn't just about layering plastics—advanced versions use metals and composites, enabling custom-designed parts that resist wear and tear in high-stress environments like aerospace or automotive applications. By experimenting with new materials such as high-strength alloys and fiber-reinforced polymers, manufacturers can craft components that outlast their predecessors, reducing maintenance needs and increasing overall product lifespan.

Another cutting-edge approach is the integration of smart manufacturing processes, which leverage real-time data and AI-driven analytics to optimize production for durability. Imagine sensors embedded during fabrication that monitor stress points and adjust parameters on the fly, ensuring each piece meets exacting standards. Techniques like cold spray technology, where metallic particles are accelerated onto surfaces without high heat, prevent thermal degradation and produce coatings that protect against corrosion and fatigue. This hands-on, data-rich method not only fine-tunes durability but also minimizes defects, making products more reliable in demanding conditions—from industrial machinery to consumer electronics.

What truly sets these innovations apart is their holistic impact on sustainability and performance. By adopting methods such as laser cladding or ultrasonic additive manufacturing, companies can reinforce critical areas without adding unnecessary bulk, leading to lighter yet tougher products. This isn't just a technical upgrade; it's a strategic shift that resonates with eco-conscious consumers and industries aiming to reduce waste. Through continuous R&D and cross-industry collaboration, these techniques are evolving beyond niche applications, setting new benchmarks for durability that make products not only last longer but also perform better under pressure, creating value that extends far beyond the factory floor.

Tailored Solutions for Diverse Industrial Fire Safety Needs

Every industrial facility operates with unique risks, from chemical plants handling volatile substances to manufacturing sites with high-energy machinery. Given this diversity, fire safety solutions must be more than just a one-size-fits-all approach. For example, a steel mill might benefit from advanced heat detection systems to monitor furnace temperatures, while a data center would prioritize gas suppression to protect sensitive electronic equipment without water damage. By customizing strategies to specific operational environments, businesses can better prevent, detect, and respond to fire incidents, ensuring both safety and productivity.

Tailoring fire safety involves a thorough assessment of each location, considering factors like building layout, materials stored, and workforce procedures. In warehouses storing flammable goods, solutions might include automated sprinkler systems with precise coverage zones, combined with employee training on evacuation routes. For offshore oil rigs, specialized fire-resistant coatings and remote-controlled extinguishing units could be essential to combat the unique challenges posed by marine conditions. This bespoke approach not only enhances compliance with regulations but also reduces downtime and insurance costs by addressing vulnerabilities head-on.

Innovation plays a key role in developing tailored solutions, with technologies like AI-powered sensors that predict fire hazards before they escalate or modular systems that can be easily upgraded. By partnering with safety experts who understand industry nuances, companies can implement proactive measures that evolve with changing operational needs. Ultimately, this focus on customization ensures that fire safety is integrated seamlessly into daily operations, fostering a culture of prevention rather than just reaction.

Global Leadership in Reliable Fire Protection Systems

Being a global leader in reliable fire protection systems isn't just about selling equipment; it's about building partnerships that keep people safe across continents. We've earned trust by consistently delivering systems that function flawlessly in emergencies, backed by over three decades of innovation and hands-on experience in diverse environments—from high-rise offices in Tokyo to remote industrial sites in Brazil. Customers rely on us not only for cutting-edge technology but for a deep commitment to reliability that turns potential disasters into controlled incidents.

What sets us apart is our proactive approach to fire safety, which goes beyond standard compliance. Instead of offering one-size-fits-all solutions, we tailor our systems to the unique risks and operational needs of each client, whether it's a hospital requiring minimal downtime or a warehouse with sensitive inventory. By integrating smart sensors and real-time monitoring, we ensure early detection and rapid response, reducing both damage and disruption. This focus on customization and continuous improvement has solidified our reputation as a go-to expert in the field.

Our leadership is also reflected in our global network of certified technicians and partners who provide 24/7 support and training. We don't just install systems and walk away; we stay involved with regular maintenance and updates, adapting to evolving fire safety standards and technologies. This ongoing engagement helps clients navigate complex regulations and enhances long-term resilience, making us a reliable ally in protecting assets and lives worldwide.

Future Trends in Gate Valve Technology and Safety Compliance

While gate valves have long been staples in industrial fluid control, recent technological shifts are poised to redefine their role. One prominent trend centers on the integration of smart sensors and IoT connectivity. Rather than merely opening or closing a flow, next-generation gate valves are being equipped with real-time monitoring capabilities that track parameters like pressure differentials, temperature fluctuations, and valve position with pinpoint accuracy. This data isn't just logged; it's wirelessly transmitted to central control systems, enabling predictive maintenance. Imagine a scenario where a valve alerts operators to abnormal friction or potential leakage before a failure occurs—this proactive approach slashes downtime and enhances operational safety dramatically.

Material science is another frontier driving innovation, particularly in harsh environments like chemical plants or offshore oil rigs. Traditional materials like cast iron or bronze are giving way to advanced alloys and composites that resist corrosion, erosion, and extreme temperatures more effectively. For instance, the use of super duplex stainless steels or ceramic-coated components can extend valve lifespans in aggressive media, reducing the risk of catastrophic leaks. Coupled with improved sealing technologies—such as resilient seats that maintain integrity under high-cycle operations—these advancements ensure that gate valves not only perform reliably but also meet stringent safety standards without constant manual oversight.

On the regulatory front, safety compliance is evolving from static checklists to dynamic, data-driven frameworks. Global standards like ISO 5208 and ASME B16.34 are being updated to incorporate requirements for digital documentation and performance validation. This means manufacturers must now design gate valves with embedded compliance features, such as tamper-proof logs of maintenance history or automated shut-off mechanisms triggered by safety thresholds. As industries prioritize sustainability and risk reduction, future trends will likely emphasize eco-friendly designs—think valves that minimize fugitive emissions or use biodegradable lubricants—blending technological prowess with environmental stewardship to set new benchmarks in safety and efficiency.

FAQ

UL (Underwriters Laboratories) and FM (Factory Mutual) certifications confirm that the fire safety gate valves meet rigorous industry standards for reliability and performance under harsh conditions, ensuring they function correctly during emergencies to contain flames and suppress fires effectively.

Top factories employ advanced materials like high-grade stainless steel or alloys, coupled with precision engineering and stringent quality control, to guarantee that valves withstand extreme temperatures, corrosion, and operational stress without failure over time.

This factory integrates cutting-edge technologies like automated manufacturing processes and smart valve designs with real-time monitoring capabilities, offering enhanced customization and proactive maintenance features that boost safety and efficiency.

Superior manufacturing ensures gate valves provide reliable shut-off control during fires, preventing spread and minimizing damage—critical for protecting lives, assets, and operational continuity in high-risk environments.

By using eco-friendly materials, implementing energy-efficient production methods, and designing valves for longevity and recyclability, the factory reduces waste and environmental impact while maintaining high safety standards.

Valves undergo extensive testing, including pressure endurance, leak resistance, thermal cycling, and fire exposure simulations, all verified by independent UL and FM auditors to ensure compliance with strict safety protocols.

The factory engages closely with clients to understand specific needs, such as custom sizes or materials, allowing for bespoke designs that optimize valve performance for unique applications and regulatory challenges.

With a robust network of suppliers and strategic distribution hubs, the factory maintains inventory flexibility and rapid shipping options, minimizing delays to meet tight deadlines in emergency installations or upgrades.

Conclusion

The gate valve factory excels in manufacturing high-quality products, as highlighted in its focus on core production excellence and innovative techniques that enhance durability. By integrating advanced manufacturing methods, the facility ensures that each valve meets rigorous standards, specifically through UL FM certification, which significantly elevates fire safety benchmarks. This commitment to innovation and durability positions the factory as a leader in providing reliable fire protection systems, tailored to diverse industrial needs, from commercial buildings to hazardous environments.

Looking ahead, the factory anticipates future trends in gate valve technology and safety compliance, reinforcing its global leadership in the industry. By offering customized solutions and staying ahead of regulatory developments, it not only addresses current fire safety challenges but also prepares for emerging demands. This forward-thinking approach ensures superior fire safety solutions, making it a trusted partner for clients worldwide seeking resilient and certified protection systems.

Contact Us

Contact Person: George

Email: [email protected]

Tel/WhatsApp: 13863633883

Website: https://www.es-fire.com